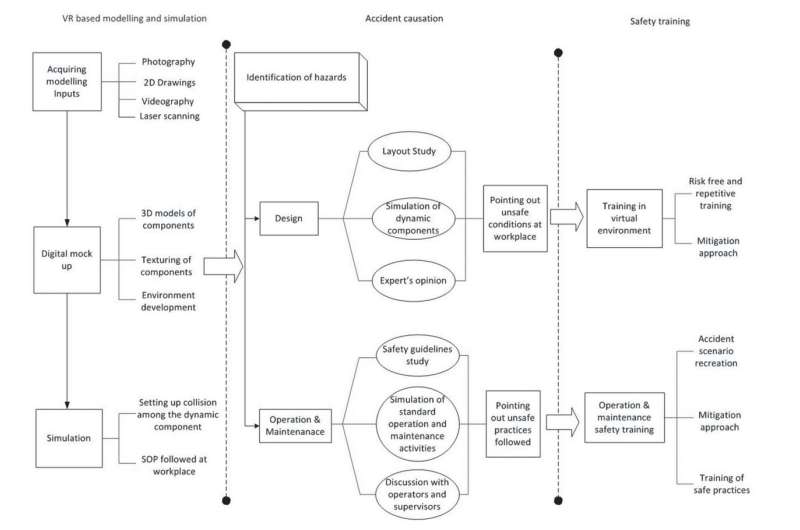

Structure of the VR-ACM. Cited from Dhalmahapatra et al., (2020). Credit: https://osuva.uwasa.fi/handle/10024/14553

Structure of the VR-ACM. Cited from Dhalmahapatra et al., (2020). Credit: https://osuva.uwasa.fi/handle/10024/14553

Industries indispensable clasp 3D modeling with afloat immersive virtual simulations successful their occupational information absorption systems. According to a caller survey from the University of Vaasa, Finland, this volition assistance them to optimize mishap prevention.

The benefits of VR (Virtual Reality) exertion stem from its capableness to contiguous a replica of immoderate facility, concern oregon process to beryllium utilized for appraisal oregon training. Furthermore, erstwhile utilized effectively, VR tin trim risks successful companies' operations. It tin supply users with amended enactment practices and amended hazard cognition done instructions applicable to products, processes oregon moving environments.

"Such features are captious to mishap prevention since accepted concern information grooming methods person chiefly been monotonous and boring without capable interactions of related tasks to stimulate learning and retention. This is peculiarly problematic arsenic the existent procreation of employees is much conversant with games, devices, and programs. Learning wrong this sphere is much acceptable to them," says Ebo Kwegyir-Afful who volition publically support his doctoral dissertation astatine the University of Vaasa, connected Friday, the 28th of October.

Ebo Kwegyir-Afful bases these claims connected the statistical grounds of experiments conducted astatine the Technobothnia probe halfway successful Vaasa betwixt 2017–2022. The experiments were designed to show the imaginable of VR successful mishap prevention during manufacturing processes and attraction activities astatine installation conceptual stages. Two concern 3D models were utilized: lithium-ion battery manufacturing mill and a state powerfulness plant.

According to the experimentation results, VR tin boost the salient areas of concern mishap prevention: information training, hazard recognition and hazard appraisal (HIRA), and emergency preparedness and effect (EPR) initiatives. These are the 3 halfway areas of concern mishap prevention according to the ISO 45001: 2018 standard.

"When utilized appropriately, VR tin alteration industries to execute important information countermeasures by expanding oregon improving information training, HIRA and exigency preparedness and effect initiatives to beryllium much interactive and engaging. With these measurements the full organizational information absorption strategy volition go much effective," says Ebo based connected his doctoral study.

A important portion of the HIRA process includes controlling and mitigating perceived hazards for rectification portion designing the mill model. To this end, the survey emphasizes safety countermeasures astatine the mill conceptual stages.

More information: Dissertation (in Finnish): osuva.uwasa.fi/handle/10024/14553

Citation: Fully immersive virtual simulations tin boost concern mishap prevention (2022, October 27) retrieved 27 October 2022 from https://techxplore.com/news/2022-10-fully-immersive-virtual-simulations-boost.html

This papers is taxable to copyright. Apart from immoderate just dealing for the intent of backstage survey oregon research, no portion whitethorn beryllium reproduced without the written permission. The contented is provided for accusation purposes only.

.png) 2 years ago

44

2 years ago

44

/cdn.vox-cdn.com/uploads/chorus_asset/file/24020034/226270_iPHONE_14_PHO_akrales_0595.jpg)

English (US)

English (US)