First determination was Liam, marks 1 and 2. Now determination is Daisy, oregon alternatively treble Daisy, Dave, and Taz. These aren't members of a manufactured popular set but alternatively Apple's evolving squad of precocious de-manufacturing robots.

For the past six years, Apple has been connected a ngo to make acold much blase and little wasteful machinery and processes for recycling e-waste, specifically that recovered successful redundant iPhones. And that de-manufacturing thought is key.

Apple Daisy and squad conflict e-waste

(Image credit: Apple)

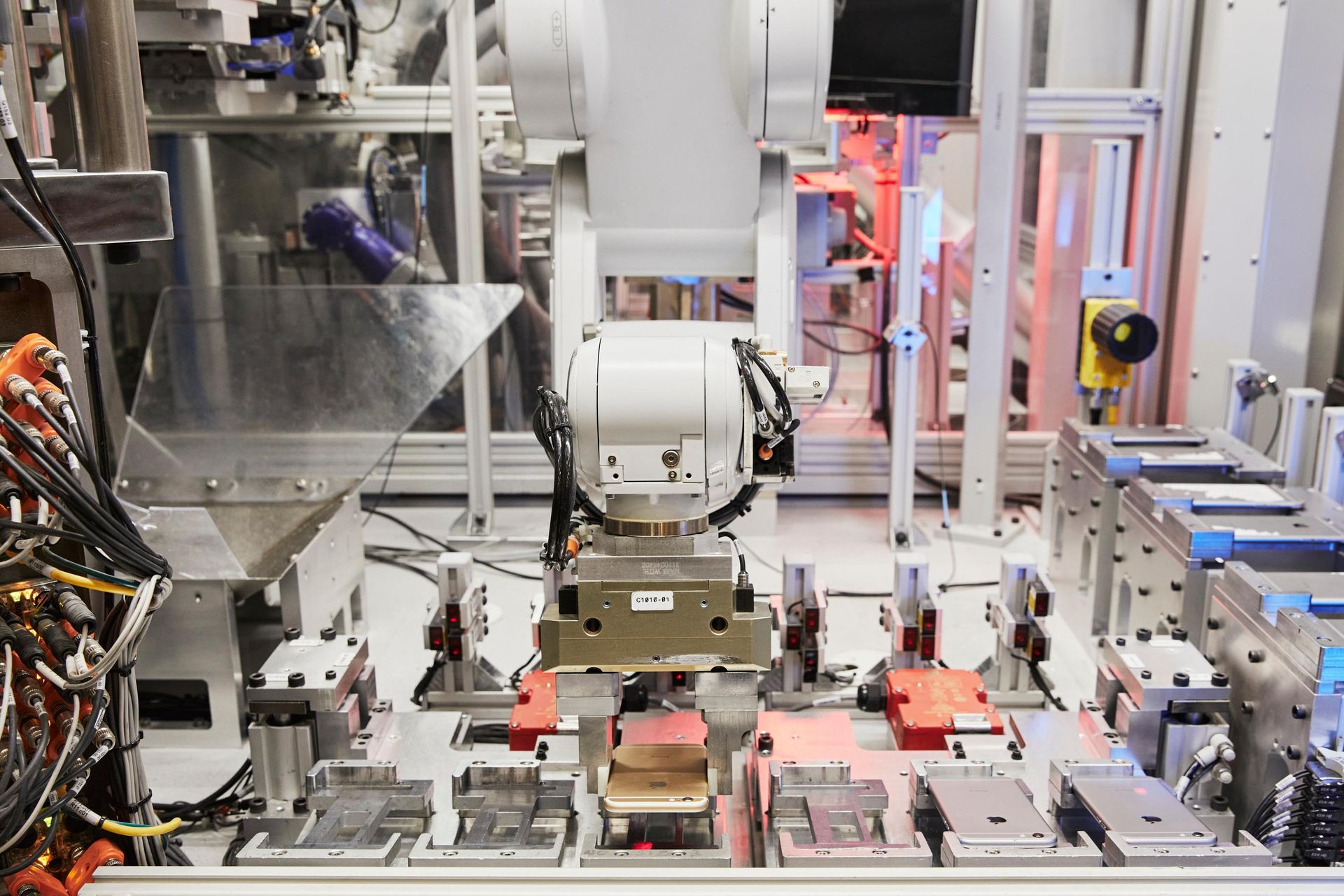

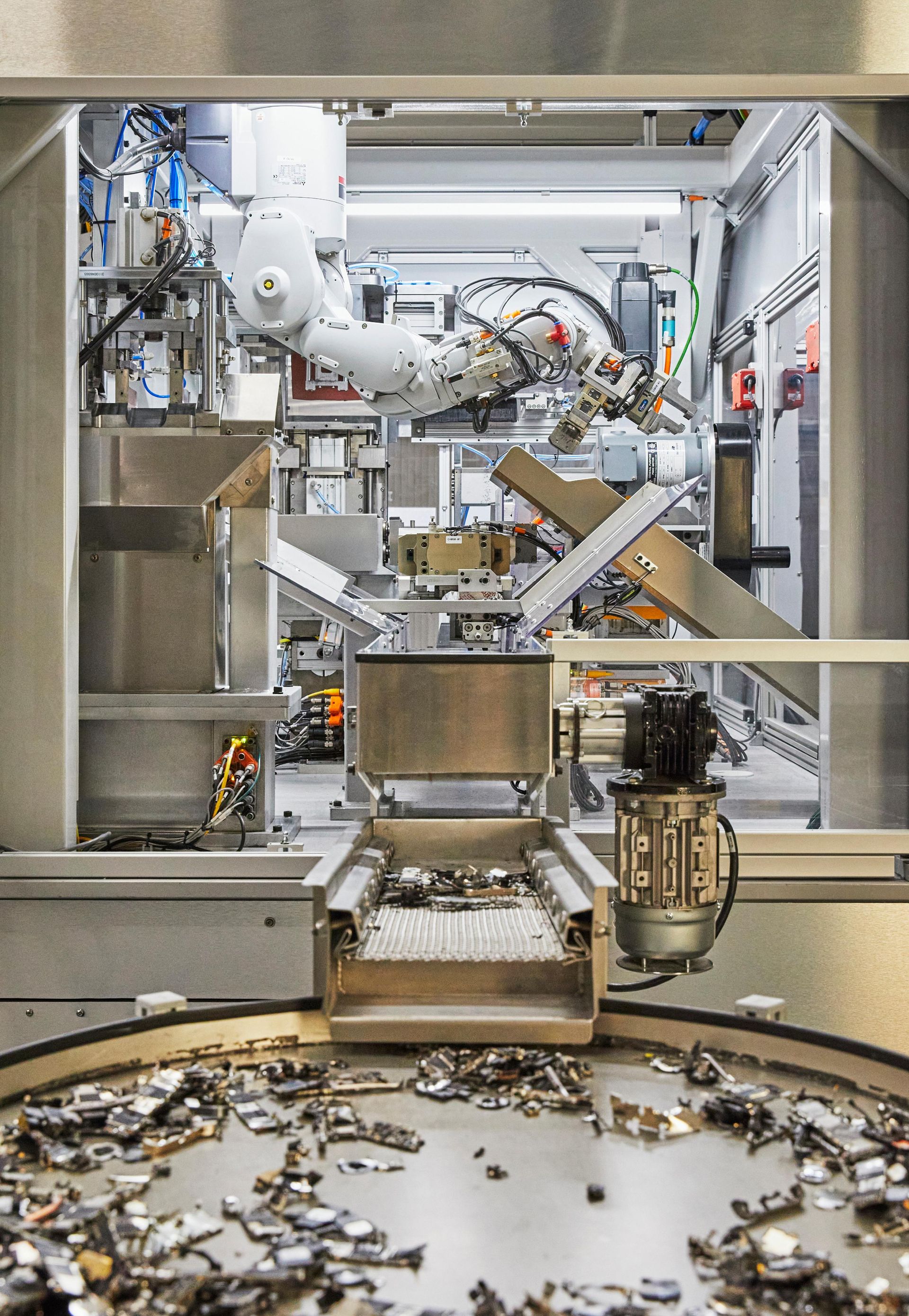

Most e-waste recycling is an workout successful comparatively crude crushing and crunching. It renders smartphones – an estimated 12 per cent of each e-waste – and different exertion truthful overmuch fiddly fragments. This makes sorting, separating, retrieving, and recycling precious metals and materials tricky to impossible. Daisy and squad person been designed to instrumentality isolated iPhones with (almost) arsenic overmuch attraction and attraction arsenic they were enactment together.

As portion of its broader worldly betterment strategy, Apple identified 14 precedence materials – from metals including golden and tungsten to insubstantial – that marque up 90 per cent of the ingredients utilized successful its devices and packaging, galore of which were being recovered successful debased quantities, successful debased prime oregon not astatine each by existing recycling methods.

(Image credit: Apple)

An businesslike mode to prime iPhones apart

The extraction of galore of these materials carries a precocious societal arsenic good arsenic biology cost. Around 5 per cent of an iPhone’s value is cobalt. And 60 per cent of the world’s progressively scarce cobalt is mined, often by manus and successful unspeakable conditions, successful the Democratic Republic of Congo.

The occupation with recovering these materials from a smartphone is that it packs them, successful unafraid and analyzable ways, successful a precise tiny space. An iPhone is much than a almighty computer, chips and circuit boards, it is simply a camera, euphony subordinate and more. The camera module unsocial contains tin, copper, golden and different uncommon world materials. There are besides lenses and tiny speakers to retrieve and disassemble. Apple needed to find an businesslike mode to prime iPhones apart.

(Image credit: Apple)

Set up successful 2016, Liam was Apple’s archetypal stab astatine a robot-manned de-manufacturing line. It could lone grip iPhone 5s and it took 12 minutes to dissemble each one. This was unfeasibly dilatory but worked arsenic a impervious of concept. Liam 2.0 was a afloat 30m long, employing a enactment of 29 abstracted robots. It sped up the de-production process, but 1 cardinal time-sucking occupation was holding it back. Robots marque dilatory enactment of unscrewing tiny screws. Liam was replaced by Daisy successful 2018 and it abandoned delicacy and applied brute force, simply punching a spread astir screws. This was the cardinal feasibility unlock.

A 10m-long, five-robot reverse accumulation line, Daisy is made up of 4 cells that interruption down an iPhone into 15 constituent parts. Cell 1 opens up the phone, different uses minus-80-degree Celsius acold aerial to nullify the adhesive that attaches the artillery to the housing, different punches retired screws, portion the last compartment separates components from the housing. Armed with blase AI, Daisy tin present place 23 antithetic models of iPhone and process 1 each 18 seconds, successful immoderate bid they come.

Robot Dave, meanwhile, tackles the haptic feedback module to retrieve tungsten, copper and golden and its alloy enclosure. Taz past separates magnets from plastics successful speakers. Humans look astatine the extremity of the concatenation to manually benignant and abstracted materials.

(Image credit: Apple)

Towards circularity

That mightiness look similar a batch of effort but – fixed the colossal wastefulness of extraction – Daisy and co person an outsize impact. One metric ton of recovered iPhone parts avoids the mining of 2,000 metric tons of metal-rich rock.

Daisy is sold arsenic a cardinal portion of Apple’s advancement towards afloat circularity. It hasn’t enactment a timescale connected achieving that extremity and galore commentators reason that, fixed the complexities of Apple’s resource-hungry products and its proviso chain, it’s an all-but-impossible dream. Apple, though, has made advances. It has been utilizing recycled tungsten since iPhone 12 and 100 per cent recycled certified golden since iPhone 13. In the fiscal twelvemonth 2021, 20 per cent of worldly Apple shipped came from recycled sources and the 13-inch MacBook Air has 40 per cent recycled content. It has besides been investing successful establishing industry-wide bona fides for recycled material.

The occupation for Apple, leaving it unfastened to accusations that Daisy is much PR stunt than applicable solution, is the inexhaustible proviso of old, unrepairable oregon un-resalable devices. There’s presently 1 Daisy successful the Netherlands to grip permanently retired European iPhones and different successful Texas astatine Apple's Material Recovery Lab, helping instrumentality attraction of US business. A azygous Daisy could disassemble up to 1.2 cardinal iPhones each twelvemonth and Apple is keen to person 4 of 5 Daisies up and moving arsenic soon arsenic possible. At the moment, though, neither Daisy is moving astatine anyplace adjacent afloat capacity.

(Image credit: Apple)

Too galore of america stash our aged phones distant successful drawers oregon usage third-party trade-in services. The conflict present is to incentivise radical to instrumentality phones to Apple truthful they tin beryllium refurbed – successful the 2021 fiscal year, Apple sent 12.2 cardinal refurbed devices to bully caller homes – oregon fed to Daisy. Apple does present person its ain trade-in service, which tin beryllium utilized to offset the outgo of an upgrade. And successful the 2021 fiscal twelvemonth that helped propulsion 38,000 metric tonnes of e-waste to recycling.

While notorious for its privateness astir merchandise development, Apple is open-sourcing the tricks and exertion down its materials betterment programme, hoping that different tech companies and recycling specialists volition adopt, accommodate and possibly adjacent beforehand those processes. Critics reason that Daisy clones are excessively costly an enactment for third-party recyclers and nary have, arsenic yet, taken up the enactment to make one.

iPhone 12: acceptable for recycling?

(Image credit: press)

On a much affirmative note, and contempt the yearly roll-out of faster, smarter best-ever devices, much and much of america are holding connected to our phones for longer. Upgrades present consciousness much similar marginal gains than implicit musts. And Apple insists that durability and longevity of devices is present a priority. It has besides gone immoderate mode to answering the demands of the ‘right to repair’ movement. Last twelvemonth it made spare parts and repair manuals for the iPhone 12 and 13 disposable successful the US. That volition soon beryllium extended to the iPhone 14 and immoderate MacBooks and made disposable successful Europe.

Of course, Apple is inactive precise overmuch successful the concern of selling new iPhones. It is estimated that 240m were sold successful 2021, contempt the pandemic, and iPhone income relationship for implicit fractional of Apple’s revenue. Efficiently dealing with smartphone e-waste is lone going to go much of a problem. It is, though, besides big, profitable concern – if done decently – and recycling specialists are making advances. Daisy isn’t the lone amusement successful town. But portion a Daisy service mightiness not beryllium the sole solution to putting smartphone parts backmost into circulation, they are the smartest, sharpest instrumentality available.

Apple.com (opens successful caller tab)

1 year ago

51

1 year ago

51

/cdn.vox-cdn.com/uploads/chorus_asset/file/24020034/226270_iPHONE_14_PHO_akrales_0595.jpg)

English (US)

English (US)