EMERGING TECH

EMERGING TECH

How the concern metaverse volition alteration manufacturing

Lincoln Electric Holdings Inc. is 1 of the world’s largest makers of welding equipment, with much than 42 manufacturing locations successful North America, Europe, the Middle East, Asia and Latin America — and its concern depends connected making definite capable welders are certified to usage its equipment.

For that reason, it felt it needed a schoolhouse to bid workers — but accepted grooming was slow, costly and cumbersome. So it turned to technologies much often associated with user gaming: virtual world and the metaverse.

Now, trainees don VR headsets to bash virtual welds, and they get contiguous feedback successful an immersive situation connected however consecutive their tube oregon expanse metallic welds are. If they messiness up, they tin simply reset the virtual strategy instantly and support getting better, and they don’t person to discarded materials successful repeated attempts. Once they’ve learned to bash it right, they use those skills successful existent welding utilizing Lincoln’s gear.

The result: Lincoln Electric discovered that it could bid welders successful 23% little time. And much skilled welders means a larger imaginable marketplace for its welding gear. “Virtual world tin trim clip portion expanding the proficiency of grooming programs,” Randal Kenworthy, elder spouse astatine exertion consulting steadfast West Monroe, which has Lincoln arsenic a client, told SiliconANGLE.

The hype astir the word “metaverse” has been gathering acknowledgment successful portion to Meta Platforms Inc. and others promising it’s the adjacent large exertion platform, akin to the idiosyncratic machine and the smartphone. The thought is consumers volition beryllium capable to link successful immersive integer worlds successful which they tin entertain themselves, play and socialize acold amended than they tin connected PCs and smartphones.

But there’s different imaginable acceptable of uses that whitethorn really dispersed faster, successful industries that bid workers, manufacture products oregon run infrastructure. This is what is known arsenic the concern metaverse, and it uses virtual and augmented world to blend the carnal and integer worlds to alteration however businesses design, manufacture and interact with objects.

Many of the gathering blocks of the concern metaverse are not new. What is new: the greater availability and affordability of AR and VR headsets, “internet of things” technology, and amended connectivity and computing. Taken together, they marque it imaginable to bring concern applications into the virtual world.

That has spurred a large woody of maturation for concern metaverse usage cases, including training, collaboration and integer twins, which simulate the existent world. In each of these usage cases, the quality to bring radical into immersive 3D worlds that tin reliably simulate real-world concern applications specified arsenic mill floors, components, robots oregon adjacent different radical are helping manufacture players bash their enactment faster, much efficiently and amended than before.

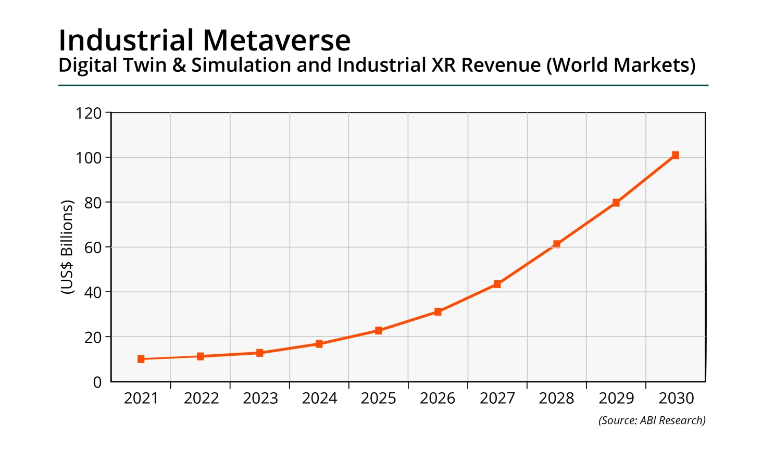

The caller revival of virtual world for consumers has led to a melodramatic emergence successful affordable AR and VR headsets for concern applications and the improvement of enterprise-ready head-mounted displays. According to a study from Market Prospects, the concern metaverse is expected to scope $540 cardinal successful gross by 2025. This is coupled with the availability of AR/VR headsets, which ABIresearch reported person shown continuous maturation successful some user and endeavor markets and volition scope 50.1 cardinal shipments and make much than $50.1 cardinal successful gross by 2026.

These devices see current-generation virtual and mixed world head-mounted displays specified arsenic the Meta Quest Pro, HTC Vive and Varjo XR3, which are each high-end enterprise-capable headsets. And augmented world headsets specified arsenic Microsoft Corp.’s HoloLens 2 and the precocious released Magic Leap 2. Heavy concern usage cases besides payment from companies specified arsenic Vuzix Corp., which produces industrial-grade, safety-rated smartglasses and headsets for fieldwork.

The concern metaverse is inactive nascent, and it faces challenges due to the fact that of precocious instrumentality costs and method difficulties. Virtual and mixed world often leads to constricted information due to the fact that of “simulator sickness” — a benignant of question sickness suffered by immoderate from immersive experiences — and the wide costs of gathering and modeling close virtual experiences.

Some of this is flooded by the usage of AR successful concern simulation for workers, but the exertion has been dilatory to develop. Metaverse applications besides necessitate a large woody of information to beryllium exchanged astatine precocious bandwidth and debased latency, which means next-generation telecommunications infrastructure needs to beryllium successful spot to enactment it.

Still, the prospects are tantalizing to galore companies, particularly since the emergence of much almighty VR and AR hardware and bundle is starting to crook the concern metaverse into a reality. As a result, immoderate companies are moving afloat velocity up to get a leap connected what could beryllium a cardinal instauration of exertion improvement for years to come.

Industrial metaverse-enabled training

Training successful the metaverse is simply a batch similar playing a video game, but that the idiosyncratic plunges into an immersive real-world script that tin hap astatine their occupation tract utilizing a virtual world headset. The usage of VR has proven to summation outcomes for idiosyncratic grooming implicit hands-on and it’s cheaper, faster and safer. “In presumption wherever I’m seeing the astir utilization of VR contiguous – immoderate of these different usage cases mightiness beryllium much prevalent moving guardant – is successful training,” said West Monroe’s Kenworthy.

Using emerging concern metaverse technologies, highly immersive experiences tin beryllium created that intimately mimic what a idiosyncratic volition spot and perceive erstwhile they’re connected the occupation tract successful virtual world models of the instrumentality they’ll interact with. People tin adjacent behave and respond likewise to the situation they volition beryllium in, helping them hole for being connected the mill level oregon field.

Another vantage of VR is that workers tin beryllium trained without the request for entree to costly instrumentality and trained anywhere, adjacent remotely oregon astatine location earlier they’re adjacent brought onto a occupation site. They tin besides beryllium trained successful perchance hazardous scenarios and environments without being enactment successful immoderate danger.

In bid to spot the benefits of grooming successful the metaverse, Lincoln Electric and Iowa State University compared 2 groups, 1 that did wholly accepted hands-on grooming and 1 that did fractional hands-on and fractional VR welding.

The results showed that welders who did the VR grooming had importantly higher levels of learning and squad interaction, with a 41.6% summation successful wide certification implicit the accepted group. And too the 23% little clip spent successful wide grooming than the accepted group, utilizing VR besides greatly reduced grooming costs by $243 per student, due to the fact that they could commencement implicit each clip without wasting materials oregon losing clip reassembling.

“Using the VR platform, students tin much rapidly larn and trial the techniques earlier going retired with the existent equipment,” said Kenworthy. “VR accelerated clip by helping them amusement adjustments successful existent clip that are required to amended their welding techniques.”

In the past 4 years, VR grooming has go adjacent much prevalent crossed manufacturing — for illustration successful automotive and aviation, wherever workers repetition rote steps connected mill floors oregon adjacent interact with robots. BMW uses VR to bid aggregate employees astatine once. Volkswagen AG formed a planetary inaugural with 10,000 employees. Aviation manufacturing elephantine The Boeing Co. chopped grooming clip by 75% with VR. Aeronautics companies besides usage metaverse technologies to bid pilots successful the air, spurred by a aviator shortage that began with the pandemic. Loft Dynamics AG has been utilizing VR simulators to bid chopper operators successful the U.S., cutting air-time grooming by arsenic overmuch arsenic 60%.

Collaboration successful the concern metaverse

Although today’s video teleconferencing exertion whitethorn enactment for supporting radical doing distant enactment and for sharing applications for collaboration, it lacks the immersive powerfulness of virtual and mixed reality. For concern metaverse applications, engineers and designers would usage headsets to bring aggregate radical astir a plan for manufacturing.

Urho Kontorri, co-founder and main exertion serviceman of Varjo Technologies Oy, the Finnish shaper of industrial-grade VR headsets, told SiliconANGLE that a large inclination for the automotive manufacture is designing the conveyance motor and chassis with distant teams.

For example, astatine automobile shaper Kia Corp., designers would make designs, but successful bid to implicit reviews, members of the squad would person to alert retired from the car maker’s European office to the plan installation successful Korea to bash a session. However, erstwhile the pandemic deed and question restrictions were imposed, that was nary longer possible.

Using Autodesk VRED’s virtual collaboration diagnostic and VR headsets to bring everyone unneurotic remotely into a azygous immersive metaverse space, designers, engineers and adjacent executives could stitchery astir a car without the request for travel. That changed the crippled entirely.

“You’d person a fewer designers from Frankfurt, immoderate from Korea, and they’d bash the aforesaid happening they did previously,” Kontorri said. “Except what would instrumentality a week due to the fact that of question clip to person that league present could beryllium done erstwhile a week, truthful 4 times arsenic often.”

Not lone did they observe that they could bash sessions much often, opening to get collaborations arsenic often arsenic each day, but the teams discovered that they could adjacent person much radical astir car designs. They were capable to standard up to 20 radical astir a car, which is astir arsenic galore arsenic you could person without the abstraction becoming truthful crowded arsenic to go unproductive.

“What was magical is that they stopped feeling that they were a outer bureau and started feeling similar they were 1 planetary squad moving together,” Kontorri explained. “That was rather a revelation.”

This aforesaid benignant of adaptation is astir apt happening passim the automotive industry, helium said. For example, Volvo Group has a precise akin setup. Using VR, the automaker discovered it could person teams bash successful a time what would usually instrumentality weeks oregon longer, and iterate connected idiosyncratic acquisition concepts rapidly by investigating them successful “real life” scenarios wrong virtual reality.

The exertion made this imaginable by allowing engineers and designers to instrumentality designs for trial drives successful VR. So teams could execute studies connected aboriginal cars earlier they were turned into prototypes and debar flaws earlier they became a occupation further down the accumulation line.

Another benignant of collaborative concern metaverse exertion successful manufacturing uses augmented reality, specified arsenic enabled by HoloLens 2. This enables a idiosyncratic successful the tract to person integer imagery overlaid implicit the existent satellite successful what the institution calls holograms. It precocious revealed that it signed Kawasaki Heavy Industries Ltd. as a caller lawsuit for the technology, joining Kraft Heinz Co. and Boeing arsenic manufacturing partners.

Workers wearing AR headsets tin usage holograms erstwhile retired connected the mill level arsenic guides erstwhile operating machinery. Then, erstwhile attempting a analyzable task oregon a repair, they tin collaborate with an adept successful bid to locomotion them done the repair process utilizing ocular cues successful their tract of vision. The headset’s sensors and cameras besides alteration distant engineers to collaborate remotely with workers regarding what’s happening connected the mill level adjacent if they’re successful a antithetic portion of the gathering oregon crossed a continent.

Digital twins and the concern metaverse

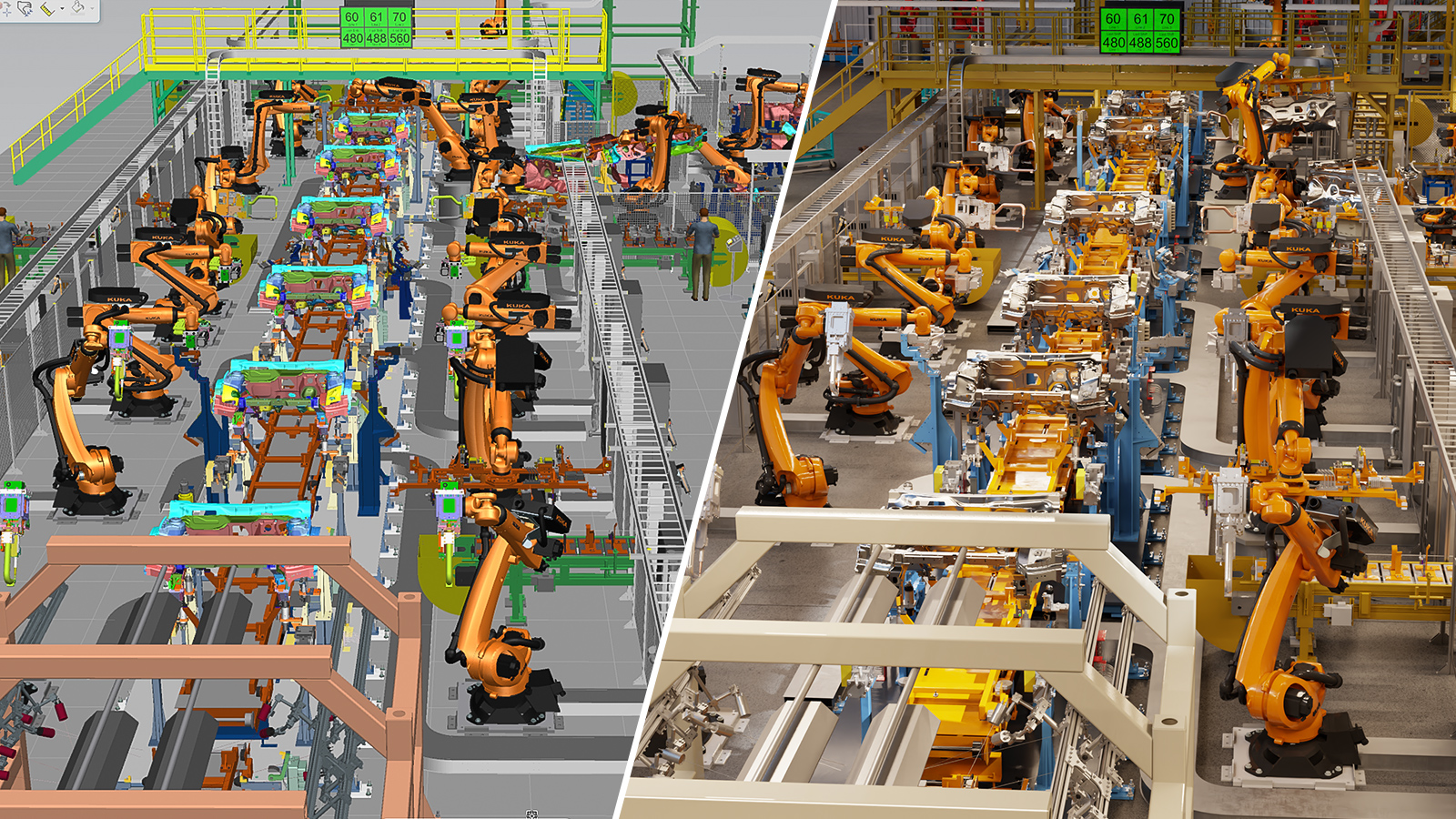

One of the much salient usage cases for the concern metaverse is “digital twins,” oregon close simulations of real-world objects specified arsenic walkways, buildings, mill floors, conveyor belts and robots.

Rev Lebaredian, vice president of Omniverse and simulation exertion astatine Nvidia Corp., said integer twins make a fig of “superpowers” for manufacturing that didn’t beryllium earlier due to the fact that abruptly endeavor customers person entree to afloat realized simulated virtual versions of their factories they tin enactment with.

These superpowers see teleportation, specified arsenic workers being capable to leap to immoderate constituent connected a mill level nary substance wherever they are successful the satellite and spot what’s going connected successful a integer twin, arsenic agelong arsenic it’s simulating what’s happening close present successful the existent one. Or they tin clip question into the past, wherever the factory’s enactment could beryllium recorded and played backmost truthful that anomalies could beryllium viewed to spot however they happened – oregon adjacent better, clip question into the future, by speeding up the simulation and watching what volition happen.

Digital twins besides let designers to physique full apparatus oregon mill floors successful virtual prototypes and simulate them earlier they enactment them into existent production. The purpose is to spot however they volition run and spot if determination volition beryllium immoderate imaginable problems. It permits them to experiment, optimize and streamline them earlier imaginable anomalies hap successful the existent world, frankincense reducing the hazard of failures oregon information issues for quality workers.

Tony Hemmelgarn, president and main enforcement of Siemens Digital Industries Software, told SiliconANGLE that Siemens has been utilizing integer twins successful its ain manufacturing processes and with customers for galore years. What the concern metaverse brought to integer twins is broad simulation.

“I retrieve the archetypal clip I did a 3D model, a 3D wireframe – earlier you had coagulated modeling,” Hemmelgarn said. “You went from 2D drawings, which is wherever the concern each started, to a 3D wireframe. And I retrieve the archetypal clip I rotated 1 astir connected a surface and idiosyncratic down maine said, ‘Wow, wherefore would you ever request much than that?’”

With the advances successful concern metaverse technologies, engineers tin spot full mill floors with afloat comprehensive, immersive views and simulate with confidence. Now, Hemmelgarn said, “teams tin travel unneurotic and spot it. I deliberation that’s that existent committedness of the concern metaverse.”

That way, Lebaredian explained, “we summation each these superpowers by having a integer twin. All of that is babelike connected having this close exemplary of the real-world happening and keeping them successful sync with the integer one. If you tin bash that, I deliberation you tin ideate galore things successful the manufacture you tin do. I mean, what can’t you bash with a teleportation and clip instrumentality and 1 that lets you research aggregate imaginable futures?”

One happening astir the manufacture that came arsenic a astonishment for Nvidia, Lebaredian said, is that the institution expected that metaverse technologies would archetypal unfold done industries done amusement – wherever VR is already broadly utilized — past architecture and design, and yet manufacturing.

Instead, the inverse happened. Manufacturing came first. Lebaredian said helium believes the crushed is due to the fact that the systems and factories themselves are highly analyzable and necessitate the capableness to simulate the aboriginal to optimize and trim costs – 1 of the superpowers, if you will, of integer twins.

A 2022 Capgemini survey of organizations utilizing integer twins noted that organizations noted that participants person seen, connected average, a 15% betterment successful sales, turnaround times and operational efficiency. Of those surveyed, they besides saw improvements of up to 25% successful strategy show and up to 16% betterment successful sustainability done their use. According to MarketsandMarkets, the integer twins marketplace unsocial was estimated astatine $6.9 cardinal successful 2021 and is projected to turn to $73.5 cardinal by 2027.

Much of this involvement has been fueled by the complexity of factories and the request to recognize amended the mode antithetic systems interact, arsenic good arsenic however the pandemic affected readying and operation astatine ample scale. Suddenly galore manufacturing operations needed to find a antithetic integer translation pathway to see adjacent infinitesimal details from the archetypal infinitesimal onward. Digital twins – arsenic accurately simulated arsenic imaginable – bash that.

This besides captured the involvement of Boeing, which announced successful December 2021 that it intends to usage integer twins and the concern metaverse to nexus its full proviso concatenation for gathering aircraft. The anticipation is that the immersive powerfulness of simulating designs, parts and manufacturing processes successful the immersive metaverse volition drawback flaws earlier they are acceptable and assistance bring craft from the drafting array to marketplace overmuch much quickly.

The aerospace shaper intends to play the agelong crippled by gathering up the integer tools needed to marque that hap with the assistance of seasoned engineer Linda Hapgood, who is champion known for taking the 767 tanker’s wiring bundles and turning them into 3D models. After that, workers were outfitted with tablets and HoloLens AR headsets for operating connected the engines, which improved prime by 90%. The effort to bring the proviso concatenation into the metaverse volition impact much than 100 engineers and physique connected those aboriginal successes.

The concern metaverse holds a large woody of committedness for manufacturing with opportunities for grooming that person already displayed important results. Both virtual and augmented world tin propulsion unneurotic teams from crossed the satellite to collaborate connected projects arsenic if they are successful the aforesaid room. It besides gives technicians successful the tract the quality to propulsion successful assistance from extracurricular who tin overlay accusation connected their vision. The summation of integer twins has besides opened up full caller “superpowers” for concern and concern usage cases.

Advances successful augmented and virtual world devices volition thrust adjacent much opportunities for concern metaverse applications going forward. But what whitethorn bring the astir for concern usage cases volition is information integration and instrumentality learning for the 3D models that the immersive simulation volition beryllium on. That volition beryllium particularly important arsenic much industries statesman to augment much of their proviso chains with metaverse applications, including onboarding their workers with training, collaboration and integer twins, with much photorealistic and real-to-life physics simulations.

All that means the impacts of the metaverse are apt to beryllium much evident successful coming years successful manufacture than among the consumers the technologies’ creators primitively imagined.

.png) 1 year ago

76

1 year ago

76

/cdn.vox-cdn.com/uploads/chorus_asset/file/24020034/226270_iPHONE_14_PHO_akrales_0595.jpg)

English (US)

English (US)