The quality to 3D scan, sphere and yet transcript a portion of past is undoubtedly 1 of the champion uses for the technology.

Designers astatine California-based institution Studio FATHOM focused connected precocious exertion combined with a specialization successful 3D penning and additive manufacturing; They worked with different companies astir San Francisco to recreate Michelangelo’s celebrated Pieta, on with 27 different works by Renaissance masters.

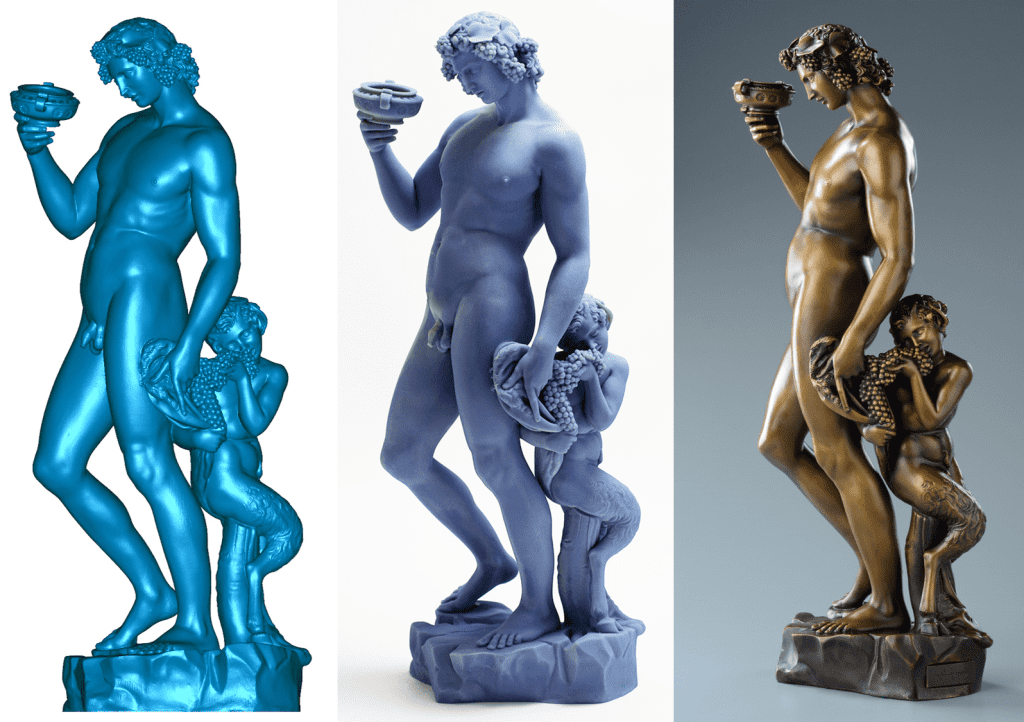

During the concern – which besides includes metallic casting institution Artworks Foundry and 3D scanning institution Scansite – a constricted fig of flawless reproductions of Michelangelo’s artwork tin beryllium produced astir from different broadside of the world. The experts from these 3 companies volition make 1 of the astir precocious 3D copying projects ever completed.

While sculptors person been utilizing the aforesaid stereotypical metallic casting techniques for centuries, the operation of 3D scanning and printing offers a much seamless and sustainable mode to reproduce the classics.

“Now we person the quality to reproduce thing that stays beauteous faithful to the archetypal piece,” says Piero Mussi, laminitis of the Artwork Foundry. “And that has ne'er been done successful the past.” After 40 years of utilizing the mislaid wax method helium learned from metalworkers successful Italy, Mussi has combined 3D scanning and 3D printing. He sees it arsenic 1 of the astir singular developments of centuries. Although Mussi uses his accepted methods successful production, his quality to sphere details and reproduce them utilizing 3D exertion has led him to enactment 3D technology. “We person a truly bully reproduction,” Mussi said. “No creator tin bash that. Only exertion tin bash that.”

Scansite is liable for collecting scan information from the archetypal casting earlier processing the information into constituent clouds and the 3D model. After completing the last files, they springiness them to Fathom, who uses the 3D printer to make the models. Once the models are 3D printed, they manus them implicit to Musi and the Artworks Foundry, who volition usage them to marque candle molds. Candle molds are yet utilized successful the mislaid wax casting process to recreate bronzes. This process has remained unchanged for thousands of years, though it is presently utilized successful conjunction with modern 3D scanning and 3D printing technologies.

Throughout the United States, identical bronze castings are disposable successful Berkeley, California; acknowledgment to the blended usage of highly precocious manufacturing technologies, the perfection of the replicas is unprecedented.

.png) 2 years ago

44

2 years ago

44

/cdn.vox-cdn.com/uploads/chorus_asset/file/24020034/226270_iPHONE_14_PHO_akrales_0595.jpg)

English (US)

English (US)