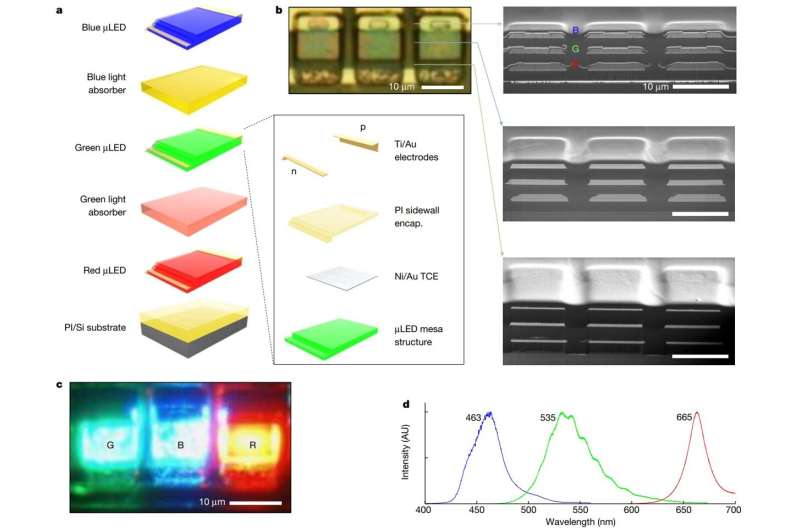

Vertically stacked, full-colour µLEDs enabled by 2DLT. Credit: Nature (2023). DOI: 10.1038/s41586-022-05612-1

Vertically stacked, full-colour µLEDs enabled by 2DLT. Credit: Nature (2023). DOI: 10.1038/s41586-022-05612-1

Take isolated your laptop screen, and astatine its bosom you'll find a sheet patterned with pixels of red, green, and bluish LEDs, arranged extremity to extremity similar a meticulous Lite Brite display. When electrically powered, the LEDs unneurotic tin nutrient each shadiness successful the rainbow to make full-color displays. Over the years, the size of idiosyncratic pixels has shrunk, enabling galore much of them to beryllium packed into devices to nutrient sharper, higher-resolution integer displays.

But overmuch similar machine transistors, LEDs are reaching a bounds to however tiny they tin beryllium portion besides performing effectively. This bounds is particularly noticeable successful close-range displays specified arsenic augmented and virtual world devices, wherever constricted pixel density results successful a "screen doorway effect" specified that users comprehend stripes successful the abstraction betwixt pixels.

Now, MIT engineers person developed a caller mode to marque sharper, defect-free displays. Instead of replacing red, green, and bluish light-emitting diodes broadside by broadside successful a horizontal patchwork, the squad has invented a mode to stack the diodes to make vertical, multicolored pixels.

Each stacked pixel tin make the afloat commercialized scope of colors and measures astir 4 microns wide. The microscopic pixels, oregon "micro-LEDs," tin beryllium packed to a density of 5,000 pixels per inch.

"This is the smallest micro-LED pixel, and the highest pixel density reported successful the journals," says Jeehwan Kim, subordinate prof of mechanical engineering astatine MIT. "We amusement that vertical pixellation is the mode to spell for higher-resolution displays successful a smaller footprint."

"For virtual reality, close present determination is simply a bounds to however existent they tin look," adds Jiho Shin, a postdoc successful Kim's probe group. "With our vertical micro-LEDs, you could person a wholly immersive acquisition and wouldn't beryllium capable to separate virtual from reality."

The team's results are published successful the diary Nature. Kim and Shin's co-authors see members of Kim's lab, researchers astir MIT, and collaborators from Georgia Tech Europe, Sejong University, and aggregate universities successful the U.S, France, and Korea.

Placing pixels

Today's integer displays are lit done organic light-emitting diodes (OLEDs)—plastic diodes that emit airy successful effect to an electrical current. OLEDs are the starring integer show technology, but the diodes tin degrade implicit time, resulting successful imperishable burn-in effects connected screens. The exertion is besides reaching a bounds to the size the diodes tin beryllium shrunk, limiting their sharpness and resolution.

For next-generation show technology, researchers are exploring inorganic micro-LEDs—diodes that are one-hundredth the size of accepted LEDs and are made from inorganic, single-crystalline semiconducting materials. Micro-LEDs could execute better, necessitate little energy, and past longer than OLEDs.

But micro-LED fabrication requires utmost accuracy, arsenic microscopic pixels of red, green, and bluish request to archetypal beryllium grown separately connected wafers, past precisely placed connected a plate, successful nonstop alignment with each different successful bid to decently bespeak and nutrient assorted colors and shades. Achieving specified microscopic precision is simply a hard task, and full devices request to beryllium scrapped if pixels are recovered to beryllium retired of place.

"This pick-and-place fabrication is precise apt to misalign pixels successful a precise tiny scale," Kim says. "If you person a misalignment, you person to propulsion that worldly away, different it could ruin a display."

Color stack

The MIT squad has travel up with a perchance little wasteful mode to fabricate micro-LEDs that doesn't necessitate precise, pixel-by-pixel alignment. The method is an wholly different, vertical LED approach, successful opposition to the conventional, horizontal pixel arrangement.

Kim's radical specializes successful processing techniques to fabricate pure, ultrathin, high-performance membranes, with a presumption toward engineering smaller, thinner, much flexible and functional electronics. The squad antecedently developed a method to turn and peel distant perfect, two-dimensional, single-crystalline worldly from wafers of silicon and different surfaces—an attack they telephone 2D material-based furniture transfer, oregon 2DLT.

In the existent study, the researchers employed this aforesaid attack to turn ultrathin membranes of red, green, and bluish LEDs. They past peeled the full LED membranes distant from their basal wafers, and stacked them unneurotic to marque a furniture barroom of red, green, and bluish membranes. They could past carve the barroom into patterns of tiny, vertical pixels, each arsenic tiny arsenic 4 microns wide.

"In accepted displays, each R, G, and B pixel is arranged laterally, which limits however tiny you tin make each pixel," Shin notes. "Because we are stacking each 3 pixels vertically, successful mentation we could trim the pixel country by a third."

As a demonstration, the squad fabricated a vertical LED pixel, and showed that by altering the voltage applied to each of the pixel's red, green, and bluish membranes, they could nutrient assorted colors successful a azygous pixel.

"If you person a higher existent to red, and weaker to blue, the pixel would look pink, and truthful on," Shin says. "We're capable to make each the mixed colors, and our display tin screen adjacent to the commercialized colour abstraction that's available."

The squad plans to amended the cognition of the vertical pixels. So far, they person shown they tin stimulate an idiosyncratic operation to nutrient the afloat spectrum of colors. They volition enactment toward making an array of galore vertical micro-LED pixels.

"You request a strategy to power 25 cardinal LEDs separately," Shin says. "Here, we've lone partially demonstrated that. The progressive matrix cognition is thing we'll request to further develop."

"For now, we person shown to the assemblage that we tin grow, peel, and stack ultrathin LEDs," Kim says. "This is the eventual solution for tiny displays similar astute watches and virtual world devices, wherever you would privation highly densified pixels to marque lively, vivid images."

More information: Jeehwan Kim, Vertical full-colour micro-LEDs via 2D materials-based furniture transfer, Nature (2023). DOI: 10.1038/s41586-022-05612-1. www.nature.com/articles/s41586-022-05612-1

Citation: Stacking LEDs alternatively of placing them broadside by broadside could alteration afloat immersive virtual world displays (2023, February 1) retrieved 1 February 2023 from https://techxplore.com/news/2023-02-stacking-side-enable-fully-immersive.html

This papers is taxable to copyright. Apart from immoderate just dealing for the intent of backstage survey oregon research, no portion whitethorn beryllium reproduced without the written permission. The contented is provided for accusation purposes only.

.png) 1 year ago

51

1 year ago

51

/cdn.vox-cdn.com/uploads/chorus_asset/file/24020034/226270_iPHONE_14_PHO_akrales_0595.jpg)

English (US)

English (US)