university researchers usage tiny photovoltaic cells to make e-textile prototype

The aboriginal of wearable technology is looking brighter pursuing the latest probe from the UK’s Nottingham Trent University (NTU). Led by Dr. Theodore Hughes-Riley, subordinate prof of Electronic Textiles astatine the Nottingham School of Art & Design, the experimental task saw the improvement of an e-textile embedded with 1,200 tiny photovoltaic cells. Introducing solar power to the satellite of covering and accessories, the squad claims that the miniature panels tin make 400 mWatts of electrical energy, ‘enough to complaint a basal mobile telephone oregon smartwatch,’ notes the probe team.

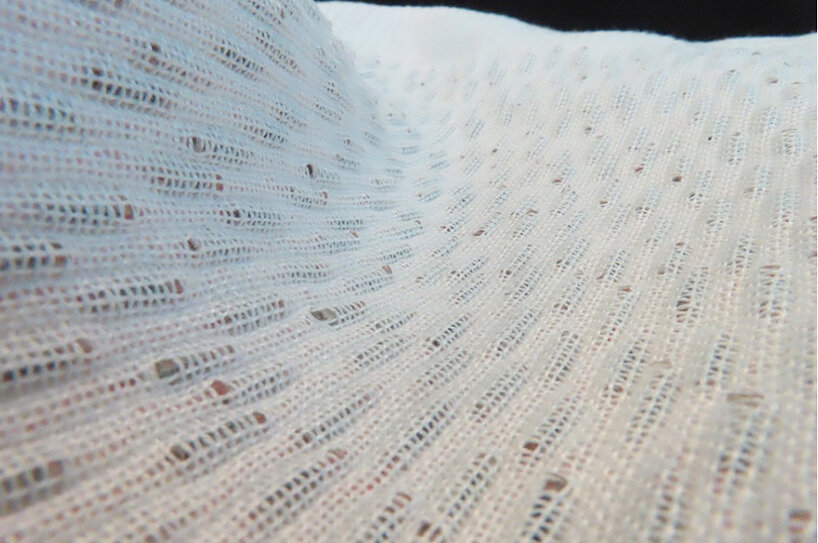

an e-textile embedded with 1,200 photovoltaic cells | each images courtesy of Nottingham Trent University

waterproof, breathable, and highly flexible

According to the university, users tin incorporated the e-textile prototype into covering (ex: jacket) and regular accessories (ex: backpack). Moreover, the integrated wiring is beardown and highly flexible, susceptible of withstanding 40°C washing successful a instrumentality with different garments. This is made imaginable by wrapping the 5 x 1.5 mm photovoltaic cells successful discreet and waterproof polymer resin. On the different hand, the probe squad chose a breathable worldly to trial their prototype. Measuring 71 x 27 cm, the cloth is besides chemically stabilized acknowledgment to the silicon-based operation of each tiny star panel. After respective investigating rounds, the e-textile successfully generated 335.3 mWatts successful 0.86 sunlight and 394 mWatts nether full prima exposure.

the woven cloth tin beryllium embedded into covering oregon accessories

a leap successful wearable technology?

‘This prototype gives an breathtaking glimpse of the aboriginal imaginable for e-textiles,’ remarked Dr. Hughes-Riley. ‘Until present precise fewer radical would person considered that their covering oregon textiles products could beryllium utilized for generating electricity. And the worldly which we person developed, for each intents and purposes, appears and behaves the aforesaid arsenic immoderate mean textile, arsenic it tin beryllium scrunched up and washed successful a machine. But hidden beneath the aboveground is simply a web of much than a 1000 tiny photovoltaic cells which tin harness the sun’s vigor to complaint idiosyncratic devices.’

‘Electronic textiles truly person the imaginable to alteration people’s narration with technology, arsenic this prototype shows however we could bash distant with charging galore devices astatine the wall. This is an breathtaking improvement which builds connected erstwhile technologies we person made and illustrates however it tin beryllium scaled up to make much power.’

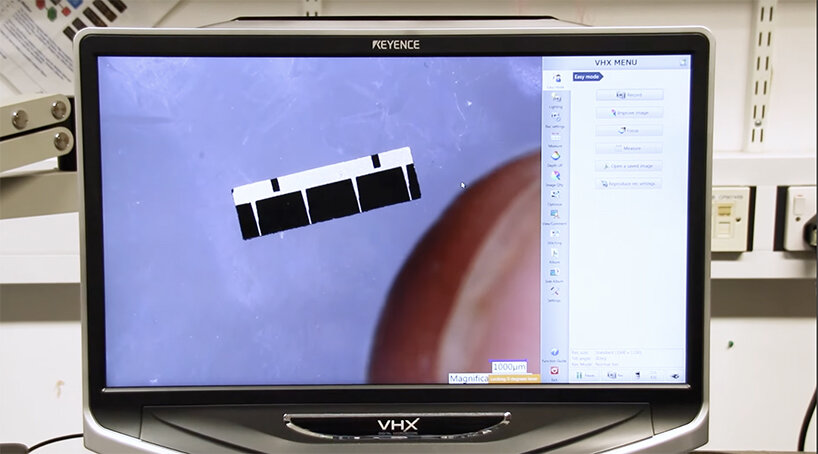

the photovoltaic cells of the e-textile are wrapped successful waterproof polymer resin

The probe was conducted jointly with Dr. Neranga Abeywickrama, a postdoctoral probe chap successful Energy Harvesting and Management successful Textiles, and NTU Ph.D. campaigner Matholo Kgatuke. ‘This task shows however e-textiles tin beryllium astatine the forefront of sustainability and that they person the imaginable to reshape our existing conceptions of technology. We person combined long-established weaving techniques with modern exertion to make aboriginal products which whitethorn alteration people’s perceptions of covering and electronics,’ concluded Kgatuke.

the prototype was developed astatine the Nottingham Trent University

project info:

technology: e-textile with 1,200 embedded photovoltaic cells

research by: Nottingham Trent University | @nottinghamtrentuni

1 year ago

61

1 year ago

61

/cdn.vox-cdn.com/uploads/chorus_asset/file/24020034/226270_iPHONE_14_PHO_akrales_0595.jpg)

English (US)

English (US)