As the satellite grapples with unprecedented levels of physics waste, Apple is fine-tuning a blase de-manufacturing robot that intercepts recyclable metallic components from millions of iPhones.

BY RYAN WADDOUPS January 10, 2023

Image courtesy of Apple …

When it comes to sustainability, we often presumption the diminishing ozone furniture and the scourge of microplastics arsenic topics of utmost concern. Less often acknowledged is e-waste, the onslaught of phones, laptops, televisions, and different electronics we blithely discard erstwhile their newer, sleeker iterations deed shelves. Though wireless exertion advances mean less cords, humanity generated a grounds 59 cardinal tons of e-waste successful 2019 alone—a fig the Natural Resources Defense Council expects volition summation 30 percent implicit the adjacent decade. These materials often incorporate specified toxic metals arsenic lead, mercury, and nickel, which tin origin respiratory and cardiovascular illness with excessively overmuch exposure.

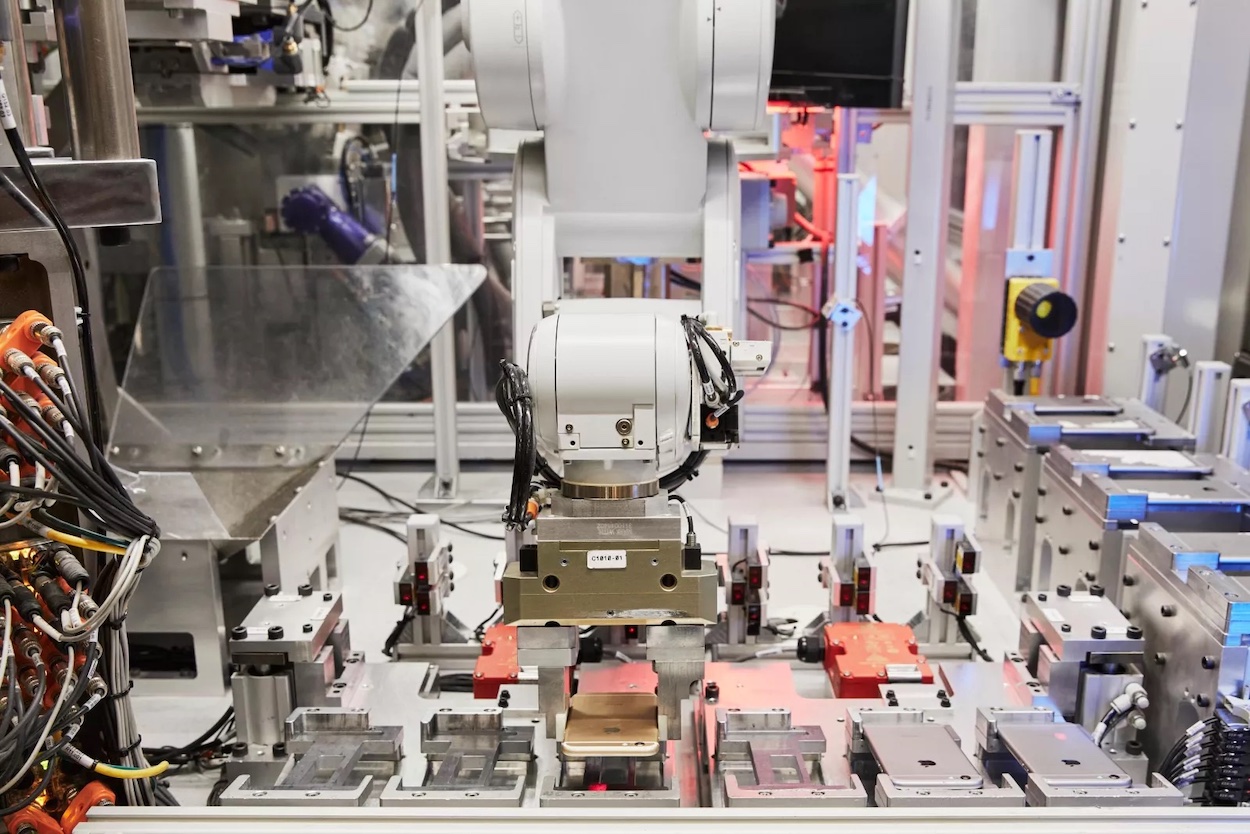

Given that planned obsolescence is simply a cardinal strategy of galore electronics companies, what are they doing to combat e-waste? Apple, the tech juggernaut that sells 240 cardinal iPhones per year, has been processing a de-manufacturing robot that tin instrumentality isolated iPhones and recycle interior metals similar golden and tungsten. It launched successful 2016 arsenic Liam, which could disassemble an iPhone 5S successful 12 minutes. After immoderate improvements, Liam relaunched 2 years aboriginal arsenic Daisy, a state-of-the-art robot that tin process 23 antithetic models successful arsenic small arsenic 18 seconds.

How does it work? Given that a multitude of metals composes a smartphone’s compact innards, Daisy is fundamentally a five-robot assembly enactment that breaks iPhones down into 15 constituent parts. One compartment forcefully punches holes astir the device’s tiny outer screws to unfastened it up; different applies frigid aerial to portion adhesive from the battery. Once the artillery is harvested, Daisy uses blase AI to abstracted metallic components from the phone’s housing, which are past hand-sorted by humans astatine the extremity of the chain. Materials are repurposed into newer products—iPhone models usage recycled tungsten and gold, and 13-inch MacBook Airs are made with 40 percent recycled material.

Images courtesy of Apple …

While Daisy signals large advancement successful the propulsion to minimize e-waste, galore hurdles remain. Apple is lone operating 2 Daisy models—one successful the Netherlands and different astatine the company’s Material Recovery Lab successful Texas—that each process up to 1.2 cardinal iPhones per year. Achieving circularity whitethorn look futile considering however Apple sells 200 times arsenic galore iPhones annually, but recycling metals has an outsize affirmative impact. According to Wallpaper, 1 metric ton of recovered telephone innards avoids mining 2,000 metric tons of rock—a notable fig fixed the deplorable conditions cobalt miners look successful Africa.

Apple isn’t the lone tech elephantine to code the mounting issue. Last year, large companies similar Dell, Microsoft, and Google joined an inaugural aimed astatine creating a circular system for electronics by 2030. The Circular Electronics Partnership, spearheaded by the World Business Council for Sustainable Development and the World Economic Forum, marks the archetypal clip large companies and manufacture experts are laying retired a roadmap toward circularity. According to the groups, though, this is lone a archetypal measurement and doesn’t screen immoderate fiscal commitments. For consumers, the champion people of enactment is to instrumentality immoderate electronics with a plug oregon artillery to a section e-waste recycling facility.

Image courtesy of Apple …

Most Viewed

Five Design-Driven Portugal Hotels For Every Taste.

From the whitewashed villages of the Algarve to originative energy–filled Lisbon to the progressively

The National Library of France Wraps Up a Breathtaking Transformation, and Other News

Our regular look astatine the satellite done the lens of design.

Struggling DTC Brand Interior Define Gets a Lifeline, and Other News

Our regular look astatine the satellite done the lens of design.

WORKac Whips Up a Futuristic Library successful Brooklyn, and Other News

Our regular look astatine the satellite done the lens of design.

Is This the Design Industry’s First Cactus Leather?

Spearheaded by L.A. interior decorator Natasha Baradaran and sourced from an integrated workplace successful Mexico,

1 year ago

63

1 year ago

63

/cdn.vox-cdn.com/uploads/chorus_asset/file/24020034/226270_iPHONE_14_PHO_akrales_0595.jpg)

English (US)

English (US)